Premium Medical Stretcher Beds for Sale | Durable & Affordable

Understanding the Modern Patient Transport Landscape

In critical patient transport and emergency medical services, the medical stretcher stands as an indispensable piece of equipment. Far beyond a simple cot, modern stretchers are engineered systems designed for rapid deployment, patient safety, and operational efficiency. The market for patient transport solutions is currently experiencing dynamic shifts, driven by technological advancements, evolving regulatory standards, and an increased demand for integrated healthcare solutions, particularly in pre-hospital and inter-hospital transfers.

Industry trends highlight a move towards lighter, more durable materials, enhanced ergonomic features to reduce strain on medical personnel, and sophisticated patient support systems. The global market for stretchers is projected to grow significantly, influenced by an aging population, rising chronic disease prevalence, and increased investment in emergency infrastructure. For instance, reports indicate the global patient handling equipment market, which includes patient stretchers, is expected to reach USD 21.6 billion by 2030, growing at a CAGR of 8.5% from 2022. This growth is largely fueled by innovations in features like hydraulic lift systems, robust locking mechanisms, and compatibility with advanced imaging equipment, ensuring seamless patient care pathways. Furthermore, the emphasis on infection control has led to demand for stretchers with easily cleanable surfaces and antimicrobial properties, reflecting a holistic approach to patient and caregiver well-being.

The Manufacturing Process of a High-Performance Medical Stretcher

The creation of a robust and reliable medical stretcher involves a meticulous multi-stage manufacturing process, ensuring peak performance under stressful conditions. Emphasis is placed on material selection, precision engineering, and rigorous quality control to meet stringent medical device standards. Let's outline the typical workflow:

- Material Sourcing & Preparation: High-grade aluminum alloys (e.g., 6061-T6 or 7005-T6 for aerospace-grade strength and lightweight properties) are typically chosen for the main frame. These alloys offer an optimal balance of strength-to-weight ratio and corrosion resistance. Stainless steel components are used for critical load-bearing joints and fasteners where superior strength and hygiene are paramount. Fabrics for the stretcher bed are often high-density polyethylene (HDPE) or vinyl-coated polyester, selected for their tear resistance, fluid impermeability, and ease of disinfection.

-

Precision Component Manufacturing:

- Cutting & Forming: Aluminum tubes and sheets undergo precise cutting using CNC laser or saw technology to achieve exact dimensions. These components are then shaped through bending, stamping, or hydroforming processes to create the stretcher's frame geometry.

- Machining: Critical connectors, hinge points, and interlocking mechanisms often require CNC machining to achieve tight tolerances, ensuring smooth operation and secure locking. This precision is vital for the safety and stability of the medical stretcher bed.

- Welding: Expert welders utilize TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding techniques to join aluminum components, creating strong, seamless joints crucial for structural integrity. Each weld is inspected for penetration and absence of defects.

- Surface Treatment: After fabrication, aluminum components typically undergo anodizing or powder coating. Anodizing enhances corrosion resistance and surface hardness, while powder coating provides a durable, chip-resistant finish that is easy to clean and sanitize, crucial for infection control in healthcare settings.

- Assembly: The various sub-assemblies (frame, wheels, mattress platform, side rails, safety straps, folding mechanisms) are meticulously assembled. This stage often involves the integration of pneumatic or hydraulic lift systems for height adjustment, ensuring smooth and controlled patient transfers.

- Quality Control & Testing: Every patient stretcher undergoes a battery of tests conforming to international standards like ISO 13485 (Medical Devices Quality Management Systems) and EN 1865 (Patient Transport Equipment). These include static load testing, dynamic load testing (simulating movement), impact resistance, fatigue testing of folding mechanisms, wheel durability, and chemical resistance to common disinfectants. Functional tests ensure all locking mechanisms, side rails, and braking systems operate flawlessly.

- Packaging & Shipment: Once certified, the stretchers are carefully packaged to prevent damage during transit, ready for distribution to hospitals, ambulance services, and emergency response units.

The target industries for these high-performance patient stretchers include emergency medical services (EMS), hospitals (ER, ICU, operating rooms), private ambulance companies, military field hospitals, and disaster response units. The advantages in these scenarios are paramount: the lightweight aluminum construction reduces caregiver strain and improves operational speed, while robust design ensures patient safety and a long service life, typically exceeding 5-7 years under regular use, minimizing the medical stretcher price over its lifecycle.

Technical Specifications and Performance Parameters

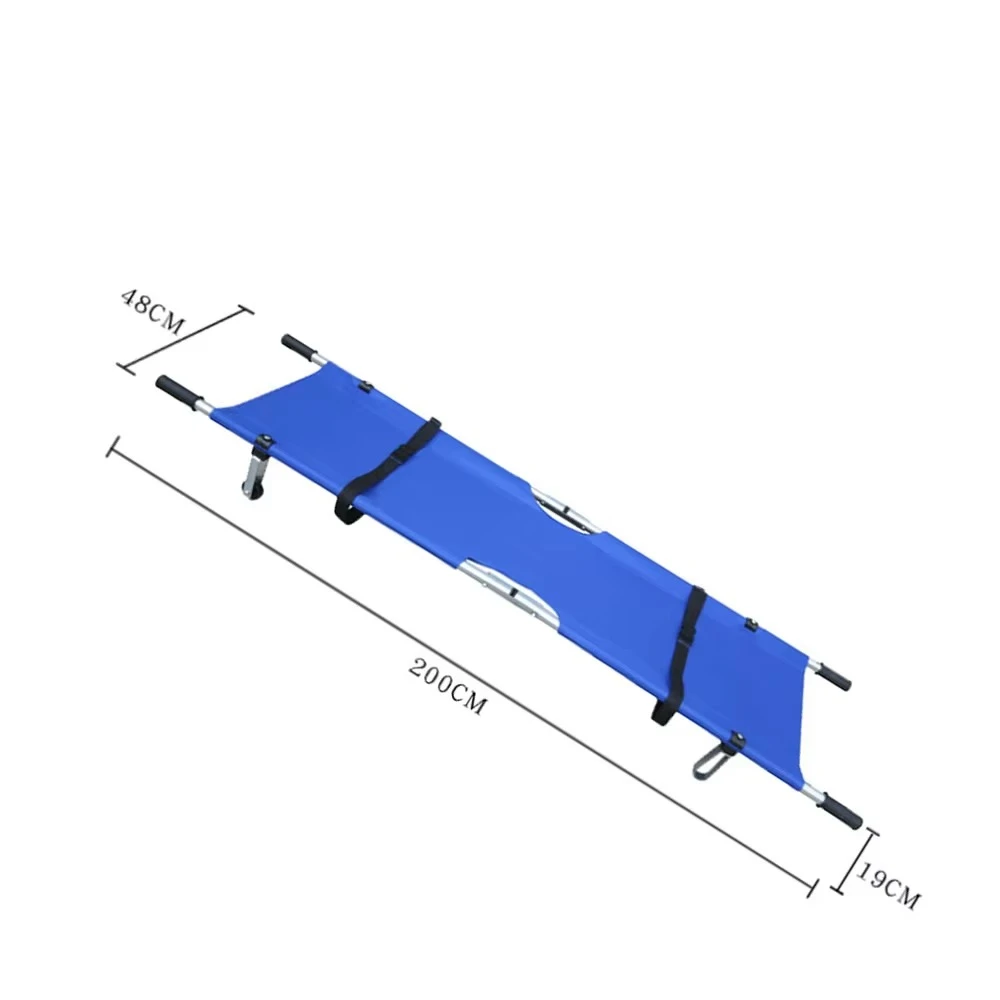

Understanding the technical specifications of a medical stretcher is crucial for procurement decision-makers. Key parameters influence functionality, safety, and compatibility with existing infrastructure. Below is a representative specification table for an advanced ambulance folding stretcher:

| Parameter | Detail |

|---|---|

| Material | High-strength Aluminum Alloy (6061-T6/7005-T6), Stainless Steel, HDPE fabric |

| Dimensions (Unfolded) | 190cm (L) x 55cm (W) x 88cm (H) (Adjustable height options available) |

| Dimensions (Folded) | 190cm (L) x 55cm (W) x 25cm (H) |

| Weight | Approximately 8-10 kg (depending on model and features) |

| Load Capacity | Up to 159 kg (350 lbs) - Certified to EN 1865 |

| Wheels | 4 swivel wheels, 2 with brakes; ø125mm medical-grade rubber |

| Safety Features | Quick-release safety buckles, folding safety lock, side rails |

| Certifications | CE, ISO 13485, FDA (as applicable for specific models/regions) |

| Adjustments | Backrest angle adjustment, height adjustment (manual/hydraulic options) |

These specifications underscore the advanced engineering involved. The lightweight nature of aluminum alloys contributes significantly to reducing the physical burden on EMS personnel, a critical ergonomic consideration. High load capacities ensure the stretcher can safely accommodate a wide range of patients, adhering to best practices in patient handling. Moreover, the integration of robust braking systems and quick-release safety buckles emphasizes patient security during transport, aligning with EN 1789 ambulance equipment standards.

Application Scenarios and Technical Advantages

The versatility and robust design of a modern medical stretcher make it indispensable across a multitude of healthcare and emergency response settings. Its application extends beyond basic patient transport, often playing a crucial role in initial assessment and stabilization.

- Emergency Medical Services (EMS) & Ambulance Transport: This is the primary application. Folding stretchers, like the Ambulance Aluminum Alloy Folding Stretcher, are designed for rapid deployment from ambulances, facilitating quick patient retrieval from various environments—be it a domestic residence, accident scene, or public area. Their lightweight nature and folding capability allow for easy maneuverability in confined spaces and efficient storage in emergency vehicles. The quick-release mechanisms and secure patient restraints are vital for safe transport at speed.

- Hospital Emergency Departments: Upon arrival, patient stretchers serve as temporary beds for initial patient assessment, treatment, and awaiting transfer to other departments. Features such as adjustable backrests and IV pole compatibility enhance the versatility for various medical procedures.

- Mass Casualty Incidents & Disaster Response: In situations requiring rapid patient triage and movement, portable and durable medical stretcher for sale units are crucial. Their ability to withstand rigorous use and provide stable platforms for patient care in challenging environments is paramount.

- Inter-hospital Transfers: For moving patients between different hospital facilities or specialist units, a comfortable and secure stretcher minimizes patient discomfort and ensures continuity of care.

Key Technical Advantages:

- Lightweight & High-Strength Construction: Utilizing advanced aluminum alloys significantly reduces the stretcher's overall weight (often 8-10 kg compared to older steel models at 15-20 kg) without compromising structural integrity. This directly translates to reduced physical strain and injury risk for EMS personnel, improving operational efficiency.

- Enhanced Patient Safety & Comfort: Integrated safety straps with quick-release buckles, robust side rails, and secure locking mechanisms prevent patient falls or movement during transport. High-density foam mattresses, often covered with impermeable, easy-to-clean materials, provide patient comfort and facilitate infection control.

- Ergonomic Design: Adjustable height and backrest angles allow caregivers to position patients appropriately for various conditions and procedures. Intuitive folding mechanisms enable rapid deployment and compact storage. The design minimizes bending and lifting, supporting caregiver well-being.

- Durability & Longevity: The use of corrosion-resistant materials and robust construction techniques ensures a long service life, even with continuous exposure to harsh environments, chemicals, and frequent cleaning cycles. This lowers the total cost of ownership (TCO) over time.

- Infection Control: Smooth, non-porous surfaces and materials that withstand repeated disinfection with hospital-grade cleaning agents are paramount. Design considerations minimize crevices where pathogens can harbor, a critical advantage in today's healthcare environment.

Vendor Comparison and Customized Solutions

Selecting the right medical stretcher vendor is a strategic decision that impacts operational efficiency, patient safety, and budget management. While many manufacturers offer standard models, key differentiators lie in quality, innovation, after-sales support, and the ability to provide customized solutions.

Key Comparison Points for Medical Stretcher Vendors:

| Feature/Aspect | High-Tier Vendor (e.g., Zhaofa Med) | Standard Vendor |

|---|---|---|

| Material Quality | Aerospace-grade Aluminum Alloys, Medical-grade Stainless Steel, Advanced Composites | Standard Aluminum, Lower-grade Steel, Basic Plastics |

| Certifications & Compliance | ISO 13485, CE, FDA, EN 1865, EN 1789 (Ambulance Vehicle) | Basic CE, sometimes ISO 9001 only |

| Ergonomics & Safety Features | Advanced hydraulic/pneumatic lifts, auto-loading, integrated restraint systems, fall prevention, multi-position locking. Focus on caregiver injury prevention. | Manual height adjustment, basic buckles, simple folding mechanisms. |

| Durability & Service Life | Designed for 7+ years heavy-duty use, extensive fatigue testing. | 3-5 years typical, less rigorous testing. |

| Customization Options | Tailored dimensions, specific accessory mounts (IV poles, monitor trays), color options, branding. | Limited or no customization. |

| After-Sales Support | Comprehensive warranty (2-5 years), readily available spare parts, technical support, training. | Basic warranty (1 year), limited spare parts availability. |

Customized Solutions: Tailoring Patient Stretchers to Specific Needs

Leading manufacturers understand that one size does not fit all. Customization plays a vital role, especially for specialized emergency services or unique facility requirements. Zhaofa Med, for example, offers tailored solutions for their Ambulance Aluminum Alloy Folding Stretcher, addressing specific operational demands.

- Dimension Adjustments: Modifying length, width, or height to fit specific ambulance interiors or tight hospital corridors. This ensures optimal integration without compromising safety or functionality.

- Accessory Integration: Custom mounts for specialized medical equipment such as defibrillators, portable ventilators, or patient monitoring systems. This seamless integration ensures critical equipment is always within reach and securely fastened.

- Material and Coating Options: For environments with extreme conditions or specific hygiene protocols, specialized antimicrobial coatings or enhanced corrosion-resistant materials can be incorporated.

- Branding and Color: Custom colors and logos can be applied for brand consistency or to differentiate units for specific departments or response teams.

The flexibility to customize ensures that the investment in a patient stretcher perfectly aligns with operational workflows and enhances overall patient care capabilities.

Real-World Application Case Studies and Customer Experience

The true value of a high-quality medical stretcher is best demonstrated through its performance in real-world scenarios and the feedback from those who rely on it daily. Our partners, including various emergency medical services and hospital networks, consistently highlight the operational benefits of our advanced stretchers.

Case Study 1: Urban EMS Deployment

An urban emergency medical service in a major metropolitan area recently upgraded its fleet with our Ambulance Aluminum Alloy Folding Stretchers. Facing challenges with aging, heavy stretchers that contributed to caregiver injuries and slow patient transfers, they sought a lighter, more agile solution. After implementing our stretchers, the service reported a 20% reduction in musculoskeletal injuries among paramedics over the first year. The stretchers' rapid deployment and compact folding mechanism significantly improved response times in congested urban environments, directly impacting patient outcomes. Furthermore, the enhanced stability and secure patient restraints provided peace of mind for both patients and responders during high-speed transport.

Case Study 2: Field Hospital Setup for Disaster Relief

During a recent disaster relief operation in a remote region, a humanitarian aid organization utilized a specialized batch of our folding medical stretcher bed units. The critical requirements were lightweight design for air transport, robust construction for challenging terrain, and ease of disinfection for infection control. Our stretchers were instrumental in setting up temporary field hospitals, allowing for rapid patient assessment and stabilization. Their durability proved crucial in environments lacking paved roads and stable infrastructure. The organization praised the quick-fold design which facilitated rapid patient evacuation and transition between different care zones, underscoring the product's resilience under extreme pressure.

"The reliability and ease of use of Zhaofa Med's stretchers have been a game-changer for our team," states Sarah Chen, Head of Operations for a regional ambulance service. "Their robust build quality, combined with thoughtful ergonomic design, means our paramedics can focus entirely on patient care without worrying about equipment failure or unnecessary strain. The competitive medical stretcher price also allowed us to equip more vehicles."

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an order of patient transport stretchers?

- A: Standard orders for the Ambulance Aluminum Alloy Folding Stretcher typically have a lead time of 2-4 weeks, depending on order volume and current inventory. For large-volume or customized orders, lead times may extend to 6-8 weeks, which will be communicated clearly at the time of quotation.

- Q: What is the warranty period for our medical equipment?

- A: Our medical stretchers come with a standard 2-year limited warranty covering manufacturing defects in materials and workmanship. Extended warranty options are available upon request for specific models or bulk purchases.

- Q: Can your stretchers be disinfected easily?

- A: Absolutely. Our patient stretchers are designed with smooth, non-porous surfaces using medical-grade fabrics and coatings that are resistant to common hospital disinfectants. They can be thoroughly cleaned and sanitized to comply with stringent infection control protocols.

- Q: Are spare parts readily available?

- A: Yes, we maintain a comprehensive inventory of spare parts for all our medical stretcher models. Parts can be ordered directly through our customer support team or authorized distributors, ensuring minimal downtime for your equipment.

After-Sales Support and Commitment

Our commitment extends well beyond the point of sale. We offer comprehensive after-sales support designed to maximize the operational lifespan and performance of your medical stretcher equipment.

- Dedicated Customer Service: Our expert support team is available to assist with technical queries, troubleshooting, and parts ordering.

- Technical Documentation & Training: Detailed user manuals, maintenance guides, and, upon request, virtual or on-site training sessions are provided to ensure your staff are proficient in operating and maintaining the equipment.

- Global Distributor Network: We work with a network of authorized distributors to provide localized support and service, ensuring efficient response times regardless of your location.

Conclusion: Investing in Advanced Patient Transport Solutions

The modern medical stretcher is a testament to sophisticated engineering, designed to meet the rigorous demands of emergency medical services and hospital environments. From its precision manufacturing using aerospace-grade aluminum to its ergonomic design and adherence to global safety standards, every aspect is geared towards enhancing patient safety, improving caregiver efficiency, and ensuring long-term reliability. As healthcare continues to evolve, the demand for advanced, customizable, and trustworthy patient transport solutions will only grow. Partnering with a reputable manufacturer that prioritizes quality, innovation, and comprehensive support is crucial for healthcare providers seeking to optimize their operational capabilities and deliver superior patient care.

References

- Grand View Research, Inc. "Patient Handling Equipment Market Size, Share & Trends Analysis Report." Published 2023.

- International Organization for Standardization (ISO). "ISO 13485:2016 Medical devices — Quality management systems — Requirements for regulatory purposes."

- European Committee for Standardization (CEN). "EN 1865:2010 Patient handling equipment used in road ambulances."

- European Committee for Standardization (CEN). "EN 1789:2020 Medical vehicles and their equipment — Road ambulances."

- Occupational Safety and Health Administration (OSHA). "Guidelines for Nursing Homes: Preventing Worker Injury."