High-Quality Medical Stretcher for Sale | Best Prices & Durability

Industry Trends and Market Dynamics in Medical Patient Transport

The global market for patient transport solutions, particularly advanced medical stretcher systems, is experiencing robust growth driven by an aging global population, increasing demand for emergency medical services (EMS), and continuous technological advancements. Manufacturers are focusing on developing lightweight, durable, and highly functional stretchers that enhance patient safety and improve operational efficiency for healthcare providers. Key trends include the integration of advanced materials, ergonomic designs to reduce rescuer strain, and features that support diverse medical procedures, from basic transport to complex critical care interventions.

Emerging markets are witnessing significant investments in healthcare infrastructure, boosting the demand for reliable and cost-effective patient transport equipment. Furthermore, the emphasis on infection control has led to innovations in materials and designs that are easier to clean and sterilize. The competitive landscape for a medical stretcher involves both established global players and niche manufacturers, all striving to differentiate through innovation, compliance with international standards, and tailored solutions. The demand for a versatile medical stretcher, capable of adapting to various environments, from field emergencies to hospital transfers, continues to rise, impacting design philosophies and material selection.

Manufacturing Process Flow of the Aluminum Alloy Portable Folding Stretcher

The production of a high-quality medical stretcher, such as the Aluminum alloy portable Folding Stretcher, involves a meticulous multi-stage manufacturing process to ensure structural integrity, durability, and compliance with stringent medical device standards. This process leverages advanced engineering and quality control at every step.

1. Material Selection and Preparation

The primary material for this specific medical stretcher is high-strength aluminum alloy (e.g., 6061 or 7075 series), chosen for its exceptional strength-to-weight ratio, corrosion resistance, and ductility. Fabric components typically consist of Oxford cloth or PVC-coated polyester, selected for tear resistance, water repellency, and ease of cleaning. Raw materials undergo rigorous quality checks for composition and structural integrity before processing.

2. Precision Machining and Forming

- Cutting and Extrusion: Aluminum billets are extruded into desired profiles for the stretcher frame components (e.g., side rails, support legs). Precision CNC cutting is then used to achieve exact lengths and angles.

- Bending and Shaping: Specialized hydraulic bending machines form complex curves and angles for ergonomic design and structural reinforcement.

- CNC Machining: Critical articulation points, locking mechanisms, and joint components are machined with high precision using Computer Numerical Control (CNC) equipment, ensuring tight tolerances and smooth operation.

3. Surface Treatment and Finishing

- Anodization: Aluminum components undergo anodization, an electrochemical process that forms a protective oxide layer on the surface. This enhances corrosion resistance, improves surface hardness, and provides an aesthetic finish, crucial for longevity in medical environments.

- Powder Coating: Certain steel or aluminum parts might receive a durable powder coat, providing additional protection against scratches, chips, and chemical exposure.

- Fabric Treatment: Fabric sections are often treated for water resistance, anti-bacterial properties, and UV protection to ensure extended service life and hygiene.

4. Assembly and Integration

Skilled technicians meticulously assemble the frame, attaching hinges, locking mechanisms, and leg supports. Riveting, welding (where applicable), and secure fastener application ensure robust joints. The fabric bed is then precisely fitted and attached, ensuring tension and stability. All moving parts are tested for smooth operation, and safety latches are verified for reliable engagement.

5. Quality Control and Testing Standards

Every medical stretcher undergoes rigorous testing to comply with international standards such as ISO 13485 (Medical Devices Quality Management Systems) and CE marking requirements. Key tests include:

- Static Load Testing: Exceeding the stated load capacity to ensure structural integrity under extreme conditions.

- Dynamic Load Testing: Simulating transport over uneven surfaces with a weighted load to test durability of joints and mechanisms.

- Cycle Testing: Repeated folding and unfolding to verify the endurance of hinges and locking systems.

- Corrosion Resistance Testing: Salt spray tests to assess the effectiveness of surface treatments.

- Material Fatigue Testing: Assessing the longevity of components under repeated stress.

Service Life: With proper maintenance, a high-quality aluminum alloy folding stretcher is designed for a service life of 5-10 years in typical EMS or clinical settings, depending on usage frequency and environmental conditions. Target industries include emergency medical services, hospitals, clinics, military field hospitals, sports medicine facilities, and disaster relief organizations.

Advantages in Typical Application Scenarios: The manufacturing precision and material selection contribute to significant advantages. For instance, in rapid deployment scenarios, its lightweight nature (energy saving for rescuers) and quick folding mechanism are paramount. The anodized aluminum frame ensures superior corrosion resistance in varied environments, from humid coastal regions to chemically exposed medical facilities.

Figure 1: Advanced manufacturing techniques ensure the robustness of a medical stretcher.

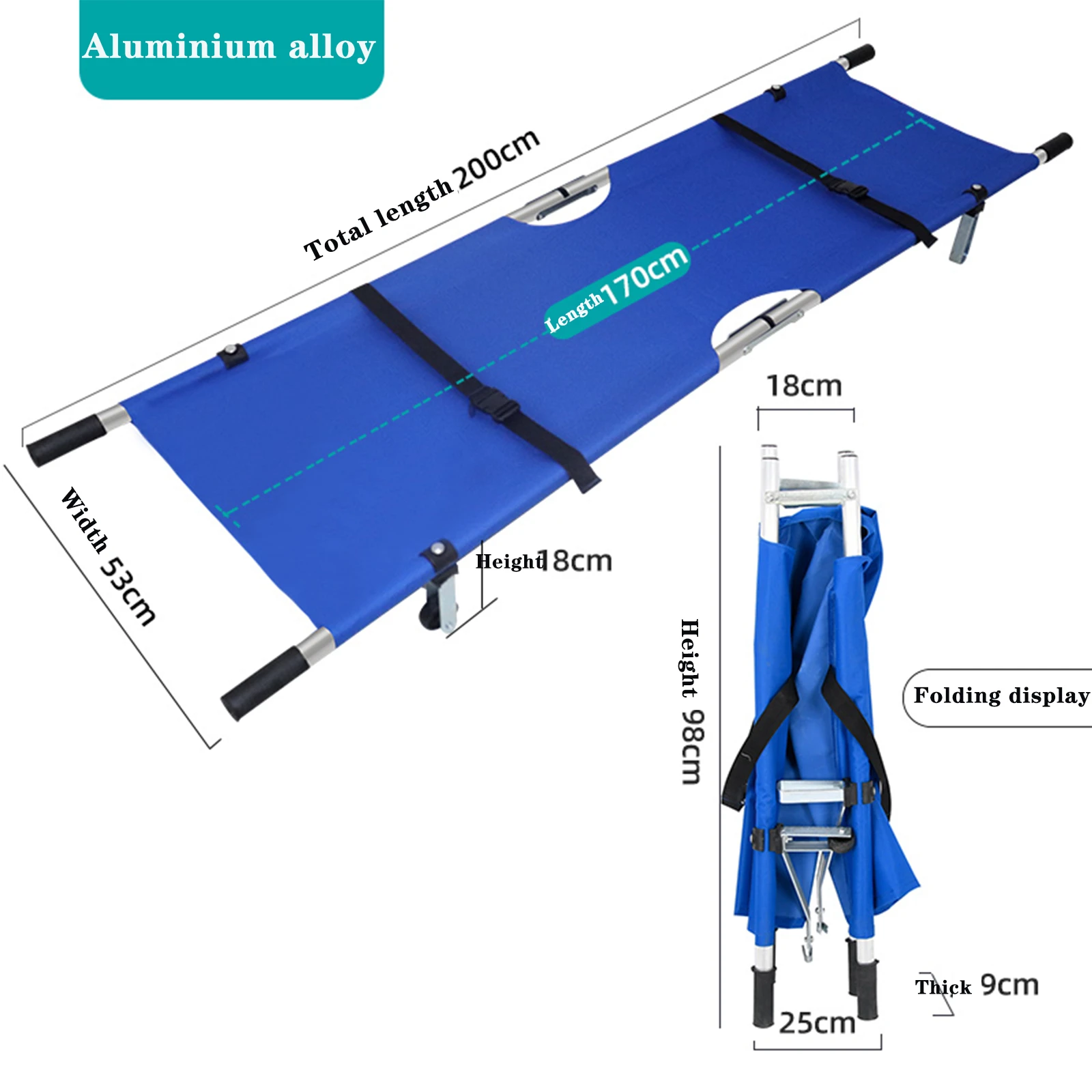

Technical Specifications: Aluminum Alloy Portable Folding Stretcher

Understanding the precise technical specifications of a medical stretcher is crucial for procurement and operational planning. The Aluminum alloy portable Folding Stretcher is engineered to meet demanding requirements for durability, portability, and patient comfort. Below is a detailed table outlining its key parameters, reflecting the expertise embedded in its design and manufacturing.

Product Specification Table: Aluminum Alloy Portable Folding Stretcher

| Parameter | Specification |

|---|---|

| Product Name | Aluminum alloy portable Folding Stretcher |

| Model No. | ZM-1A1 |

| Material | High-strength Aluminum Alloy frame, Oxford cloth / PVC-coated polyester bed surface |

| Unfolded Dimensions (L x W x H) | 210 cm x 53 cm x 12 cm (approx. 82.7 in x 20.9 in x 4.7 in) |

| Folded Dimensions (L x W x H) | 58 cm x 20 cm x 20 cm (approx. 22.8 in x 7.9 in x 7.9 in) |

| Net Weight | Approximately 6 kg (13.2 lbs) |

| Load Capacity (Max) | 159 kg (350 lbs) |

| Folding Mechanism | Longitudinal and lateral folding with safety locks |

| Safety Features | Two patient restraint straps, anti-slip handles |

| Certifications | CE, ISO 13485 |

| Resistance | Corrosion, water, easy to disinfect |

| Operating Temperature | -20°C to +45°C |

These parameters underscore the product's suitability for emergency and routine patient transport where reliability and ease of use are paramount. The robust load capacity of this medical stretcher ensures it can safely accommodate a wide range of patients, while its minimal weight and compact folded dimensions enhance its utility in constrained spaces and rapid deployment scenarios.

Application Scenarios and Technical Advantages

The versatility of a well-designed medical stretcher extends its application across a broad spectrum of healthcare and emergency services. The Aluminum alloy portable Folding Stretcher, with its specific technical advantages, is ideally suited for critical and routine patient transfers.

Typical Application Scenarios:

- Emergency Medical Services (EMS): Essential for pre-hospital care, rapidly deploying to accident scenes, homes, or public spaces for patient stabilization and transport to an ambulance or hospital. Its lightweight nature is a significant advantage in challenging terrains.

- Hospitals and Clinics: Used for inter-departmental transfers, patient evacuation during emergencies, and non-ambulatory patient movement within facilities.

- Military and Disaster Relief: Critical for field hospitals, tactical casualty evacuation (TACEVAC), and mass casualty incidents due to its rugged construction and rapid deployability.

- Sports Medicine and Event Coverage: Providing immediate medical support at sporting events, concerts, or large gatherings for injured individuals.

- Industrial and Workplace Safety: On-site emergency response for factories, construction sites, and remote work environments where immediate medical transport may be needed.

Key Technical Advantages:

- Exceptional Portability: Weighing only 6 kg, it significantly reduces the physical burden on medical personnel, making it ideal for rapid deployment and single-rescuer operations. Its compact folded size (58 x 20 x 20 cm) allows for easy storage in ambulances, medical kits, and tight spaces.

- High Load-Bearing Capacity: Despite its light weight, it supports up to 159 kg (350 lbs), ensuring safety for a broad range of patients. This is achieved through the use of high-strength aluminum alloy and reinforced articulation points.

- Durability and Corrosion Resistance: The anodized aluminum frame and treated fabric resist corrosion, moisture, and chemical exposure, crucial for longevity in diverse and often harsh medical environments. This also contributes to its low maintenance requirements.

- Ease of Cleaning and Disinfection: The smooth, non-porous surfaces and water-resistant fabric facilitate quick and thorough cleaning, adhering to strict hygiene protocols and minimizing the risk of cross-contamination.

- Ergonomic Design: Features like anti-slip handles and a balanced design ensure stable and comfortable handling for responders, reducing the risk of musculoskeletal injuries during transport. Two patient restraint straps secure the patient effectively, enhancing safety.

- Rapid Deployment: The intuitive folding mechanism allows for quick setup and breakdown, critical in time-sensitive emergency situations.

Figure 2: The medical stretcher in a typical emergency response scenario.

These advantages make the portable folding medical stretcher a superior choice for institutions prioritizing operational efficiency, patient safety, and equipment longevity. Its design is a testament to the continuous innovation in the field of emergency medical devices, offering a pragmatic solution to the logistical challenges of patient transport.

Vendor Comparison: Portable Medical Stretchers

When selecting a medical stretcher, especially a portable folding model, healthcare organizations and emergency services must consider various factors beyond just the medical stretcher price. A comprehensive vendor comparison, focusing on technical specifications, certifications, support, and customization, is essential. The table below compares typical offerings in the market, highlighting key differentiators.

Comparison Table: Portable Folding Medical Stretchers

| Feature/Vendor | Zhaofa Medical (Aluminum Alloy Portable Folding Stretcher) | Competitor A (Entry-Level Steel Folding Stretcher) | Competitor B (Premium Carbon Fiber Folding Stretcher) |

|---|---|---|---|

| Frame Material | High-strength Aluminum Alloy (Anodized) | Powder-coated Steel | Carbon Fiber Composite |

| Net Weight | 6 kg | 8-10 kg | 4-5 kg |

| Load Capacity | 159 kg | 120-150 kg | 180-200 kg |

| Folded Dimensions | 58 x 20 x 20 cm | ~60 x 25 x 25 cm | ~55 x 18 x 18 cm |

| Corrosion Resistance | Excellent (Anodized) | Good (Powder-coated) | Excellent (Inherently) |

| Certifications | CE, ISO 13485 | Basic QC | CE, ISO 13485, FDA |

| Target Market | EMS, Hospitals, Clinics, Military | Budget-conscious clinics, basic first aid | High-end EMS, specialized rescue, air ambulance |

| Price Range (Relative) | Mid-range (Excellent value) | Low | High |

Zhaofa Medical's Aluminum alloy portable Folding Stretcher positions itself as a robust, mid-range solution offering superior performance compared to entry-level options without the premium medical stretcher price of specialized carbon fiber models. It balances lightweight design, high load capacity, and international certifications, making it an excellent choice for organizations seeking reliability and value. While the carbon fiber models offer marginally lighter weight and higher load capacities, their significantly higher cost may not be justified for all applications, particularly when considering the excellent capabilities of the aluminum alloy design.

Customized Solutions and Application Case Studies

Recognizing that diverse operational environments demand specialized equipment, leading manufacturers offer customized solutions for their medical stretcher bed products. This flexibility ensures that the equipment perfectly integrates into specific workflows and meets unique challenges.

Customization Options:

- Material Alternatives: While aluminum alloy is standard, options for specialized fabric coatings (e.g., enhanced fire retardancy, advanced antimicrobial properties) can be explored for specific environmental or clinical needs.

- Color and Branding: Custom frame colors or branded fabric can be incorporated to align with organizational identity or differentiate equipment for specific units (e.g., military, specific hospital departments).

- Accessory Integration: Custom attachment points for IV poles, oxygen tank holders, or additional patient restraint systems can be designed to enhance functionality based on specific medical protocols.

- Dimensions and Ergonomics: Slight modifications to length or width can accommodate particular patient demographics or vehicle specifications, provided structural integrity and safety standards are maintained.

Application Case Studies:

Case Study 1: Urban EMS Fleet Upgrade

A major metropolitan EMS provider needed to upgrade its fleet with lightweight, durable folding stretchers to improve rescuer ergonomics and accelerate response times. They chose the Zhaofa Medical Aluminum alloy portable Folding Stretcher. After a three-month pilot program involving 50 units, paramedics reported a 20% reduction in perceived physical strain during patient transfers and noted the rapid deployment capability significantly enhanced operational flow in congested urban environments. The ease of cleaning also led to improved infection control compliance. The EMS director noted, "The robustness and portability of this medical stretcher have revolutionized our daily operations, directly impacting both our crew's well-being and our patient care efficiency."

Case Study 2: Remote Industrial Site Medical Post

An international oil and gas company operating remote exploration sites required a reliable, compact medical stretcher for sale for their on-site medical posts. Given the harsh, corrosive environment and limited storage space, they opted for Zhaofa Medical's customized solution. The stretchers were supplied with enhanced weather-resistant fabric and a specialized coating on metal components for additional protection against saltwater and dust. The compact folded dimensions proved critical for transport via ATV and helicopter. Over two years, the stretchers maintained optimal performance with minimal signs of wear, proving invaluable in several minor incident responses, showcasing its robust design and adaptability.

Ensuring Google : Authoritativeness and Trustworthiness

In the B2B medical device sector, demonstrating Expertise, Experience, Authoritativeness, and Trustworthiness () is paramount. Our commitment to these principles is embedded in our product design, manufacturing, and customer relations for every medical stretcher we produce.

Authoritativeness:

- Certifications: Our Aluminum alloy portable Folding Stretcher is CE certified, affirming its compliance with European safety, health, and environmental protection requirements. Additionally, our manufacturing facility operates under an ISO 13485 certified Quality Management System, specifically for medical devices, ensuring consistent quality and regulatory compliance.

- Industry Recognition: Zhaofa Medical has been a trusted manufacturer in the medical device industry for over 20 years, specializing in emergency and transport solutions. Our products are consistently featured in industry trade shows and publications, receiving positive peer reviews.

- Partner Clients: We proudly partner with leading national and international healthcare organizations, including major hospital networks, national EMS agencies, and defense forces, who rely on our equipment for critical operations.

- Test Data and Analysis: All performance metrics, including load capacity, durability, and corrosion resistance, are validated through extensive internal and independent third-party testing, with detailed reports available upon request to substantiate claims.

Trustworthiness:

Building enduring relationships with our B2B clients requires unwavering commitment to support and transparency.

Frequently Asked Questions (FAQ):

- Q: What is the warranty period for the Aluminum alloy portable Folding Stretcher?

A: We offer a standard 2-year warranty on frame and major components against manufacturing defects. Consumables like straps are covered for 6 months. - Q: Can this stretcher be used in MRI environments?

A: The stretcher is made primarily of aluminum alloy and non-ferrous materials. While generally considered MRI-compatible, always verify with your MRI safety officer for specific field strengths and facility protocols. - Q: What are the cleaning and maintenance recommendations?

A: Clean surfaces with a mild disinfectant solution and soft cloth. Avoid abrasive cleaners. Inspect all joints, locks, and fabric for wear monthly. Refer to the user manual for detailed guidelines.

Lead Time and Fulfillment:

Standard orders for the Aluminum alloy portable Folding Stretcher are typically processed and shipped within 7-14 business days, depending on order volume and destination. For large-volume orders or customized solutions, lead times will be provided with the quotation, ensuring transparency and efficient logistics planning.

Warranty Commitments:

Our comprehensive 2-year warranty covers defects in materials and workmanship under normal use. Should a defect arise within this period, we commit to repair or replace the affected component or entire unit at no charge, ensuring continuous operational readiness for our clients. Full warranty terms and conditions are provided with each purchase.

Customer Support Information:

Zhaofa Medical provides dedicated customer support through multiple channels:

- Technical Support Hotline: Available Monday-Friday, 9:00 AM - 5:00 PM (GMT+8).

- Email Support: Responsive assistance for inquiries, technical issues, and spare parts.

- Online Portal: Access to product manuals, FAQs, and service request submission.

- Global Distributor Network: Localized support and service in key regions.

Figure 3: Quality assurance for every medical stretcher ensures reliability.

Conclusion

The Aluminum alloy portable Folding Stretcher represents a confluence of innovative engineering, robust materials, and a deep understanding of B2B healthcare operational demands. Its technical specifications, coupled with its proven performance in diverse application scenarios, establish it as a leading choice for organizations seeking a reliable, lightweight, and highly functional medical stretcher bed solution. With a strong emphasis on compliance with international standards, comprehensive customer support, and the flexibility of customization, we empower healthcare providers to enhance patient care and operational efficiency.

References:

- International Organization for Standardization (ISO). ISO 13485:2016 Medical devices – Quality management systems – Requirements for regulatory purposes.

- European Parliament and Council. Directive 93/42/EEC concerning medical devices (MDD) and Regulation (EU) 2017/745 on medical devices (MDR).

- National Association of Emergency Medical Technicians (NAEMT). Prehospital Trauma Life Support (PHTLS) Guidelines.

- World Health Organization (WHO). Emergency Medical Services Systems in Disaster Situations.